Dr. Kasra Momeni, assistant professor of mechanical engineering and director of the Advanced Hierarchical Materials by Design Lab at Louisiana Tech University, has discovered a new mechanism for strengthening nanomaterials and tailoring their properties to build superior structures.

Momeni, in collaboration with researchers from Wright State University and the University of Göttingen in Germany, have revealed a new path for engineering nanomaterials and tailoring their characteristics. This additional dimension added to the material design opens new doors to build superior materials by engineering their atomic structure. The proposed approach can also be used to adjust the chemistry of the material, which is of importance for designing new catalytic materials enhancing the chemical processes.

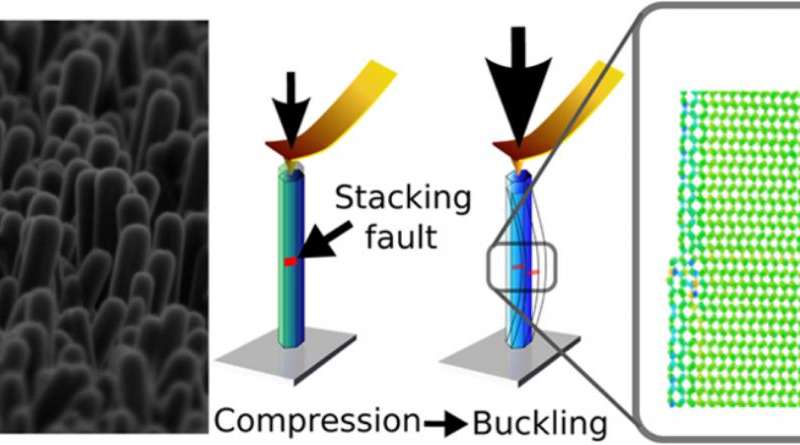

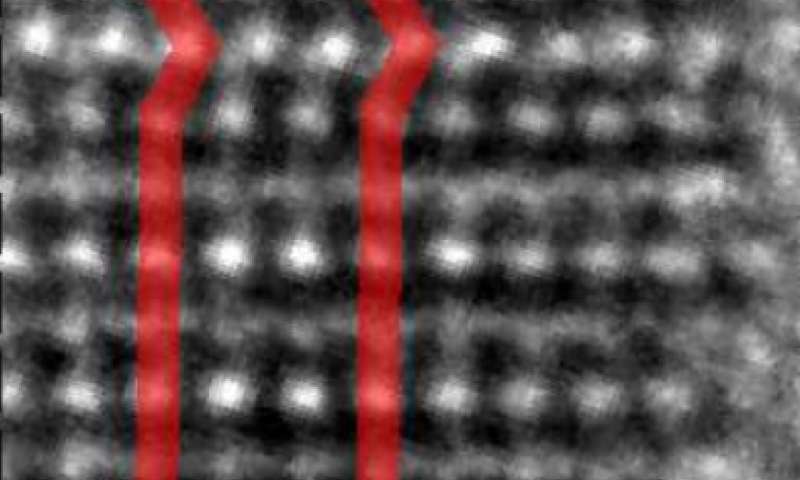

“Stacking faults in nanomaterials drastically change the stress distribution, as the long-range stress fields interact with the boundaries in these materials,” said Momeni. “The complex nature of the stresses formed in nanowires, as a result of superposition of the stress fields from surface relaxation and reconstruction as well as the stacking fault stress fields, changes the failure mechanism of the nanowires.”

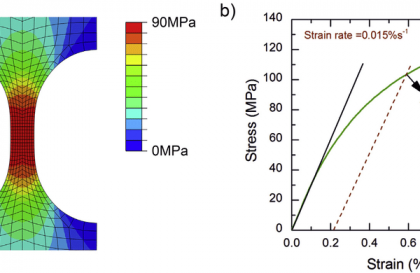

Atomistic simulations indicate that the presence of stacking faults results in an inhomogeneous stress distribution within the nanowires due to the change in the sign of stress fields on the two sides of stacking faults (i.e. compressive stress on one side and tensile stress on the other side). This inhomogeneous stress field results in a nonsymmetrical mechanical response of the nanowires under tensile and compressive loadings. The defected nanowires with diameters smaller than 1.8nm and a single stacking fault, surprisingly, have higher a yield stress compared to their counterparts with perfect structures.

“This surprising behavior is due to the interaction between the stress fields of stacking faults with the stress field of relaxed and reconstructed surfaces in thin nanowires,” Momeni said. “We expect similar results in other 1D nanomaterials with stacking faults, where inhomogeneous stresses form. The developed atomistic model paves the way to study the effect of different stacking fault distributions and engineering defects to tailor material properties.”

“Since energy harvesting is one of the key requirements in today’s age, converting mechanical forces into a useful form of energy, i.e. electrical output, is an alternative to other energy transduction modes as well as an efficient approach. There are several crystalline ceramics which convert mechanical energy into electrical energy. We introduced a new concept that mechanics of these tiny crystalline ceramic structures are dependent on atomic defects. For example, they can collapse and their mechanical properties are not as expected. Consideration of these facts will enable us to design energy harvesting devices out of such tiny structures,” explains Dr. Moumita Ghosh, leading scientist of this research from the University of Göttingen and former doctoral research scholar of the Indian Institute of Science, Bangalore.

“Dr. Momeni arrived at Louisiana Tech this past August and has hit the ground running,” said Dr. David Hall, director of civil engineering, construction engineering technology and mechanical engineering at Louisiana Tech. “His discovery of a method to strengthen materials through the interaction of atomic-level material features is a significant and fundamental contribution in computational mechanics.

The new finding reveals a non-intuitive know-how of defects in terms of mechanics at low dimension. Defect engineering in piezoelectric nanomaterials in future will enable us to realize various high quality and cost-effective vibration-based energy harvesting as well as electro-mechanical devices for biomedical research, diagnostics, and electronic applications.

The atomic arrangements of Zinc Oxide visible under a high-resolution transmission electron microscope. Here, Zn (green) represents Zinc and O (blue) represents Oxygen. The red lines showing the defect in the periodicity of atomic arrangements. The zig zag periodicity is Zinc Oxide’s original periodicity called wurtzite and the straight line is the region with defect where the original zig zag periodicity is lost. The defected region plays a significant role in the study. Credit: University of Göttingen

Read more at: https://phys.org/news/2016-09-scientists-mechanical-behavior-tiny-affected.html#jCp