At the the Tesla Cybertruck’s original 2019 launch, it was claimed that the skin would be made of the same stainless steel that is used by sister company SpaceX for its coming Starship spacecraft. Since that time, We have known that Tesla is sourcing their stainless steel panels from Finnish supplier Outokumpu Oyj. Another information that we have about these stainless steel blocks is that they are 300 series stainless Steel.

However, as an engineer we have known that steel is a very general term called for the alloys whick contain carbon, iron and other alloy elements. Particularly, it is very difficult to distinguish mechanical properties of a material by defining it as “stainless steel”. Additionally, While most of the webpages and news blogs are publishing posts about key details, bulletproof features and high durability of the CyberTruck exterior design, they are lack of technical and engineering details of the exterior material called “stainless steel”. In this post, we want to provide an engineering approach for this Cybertruck stainless steel topic. Here we go!

CyberTruck: Stainless Steel

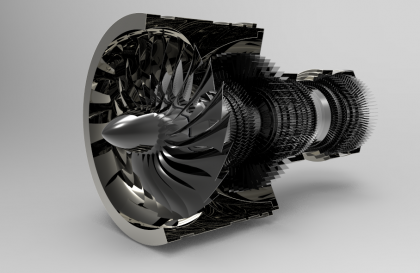

A proprietary 301-series stainless steel gives Tesla’s first pickup truck unique sales attributes while saving tooling cost. Tesla’s decision to use stainless steel for its upcoming Cybertruck, as part of what CEO Elon Musk calls an “exoskeletal” structural design, aims to give the new electric pickup strength and durability beyond that of its competitors

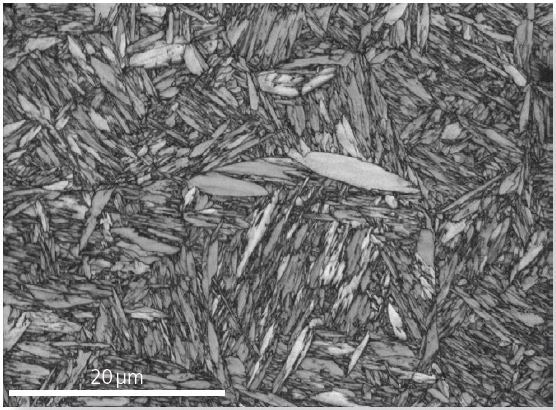

In 2020, “Tesla’s strategy with this truck is very interesting,” observed Dr. David Matlock, professor emeritus at the Colorado School of Mines’ Advanced Steel Processing and Products Research Center. Reviewing Musk’s public comments on Cybertruck online, Matlock surmises that the material is “very likely a modified version of the lean-alloyed austenitic 301 alloy.” When this alloy system is deformed or cold-worked, it transforms into a microstructure that includes austenite and martensite, primary constituents for a strong and tough metal.

Martensite is formed in carbon steels by the rapid cooling (quenching) of the austenite form of iron at such a high rate that carbon atoms do not have time to diffuse out of the crystal structure in large enough quantities to form cementite (Fe3C).

“The more you deform it, such as cold rolling, the more martensite you get. And that contributes to a significant increase in strength,” he explained. Martensitic high-strength (non-stainless) steels are increasingly used in vehicle structures to increase strength, but they achieve their hardness through heating and quenching as is done in press-hardening steel commonly used in automobiles today. By comparison, the lean austenitic stainless alloys can create martensites by cold-roll-induced transformation at room temperature, Matlock noted.

Elon Musk described this special stainless steel material which was used for Cybertruck’s exterior, “Utra-hard 30X cold-rolled stainless-steel” indicating an alloy variant developed from 300-series stainless steel.

However, Although the details of the entire bodywork is not clear, Musk stated that the panel thickness was 3mm and bulletproof to a 9mm handgun. Musk went on further to also state that the new stainless alloy (developed by Tesla for their starship rocket) could not be formed into any shapes because “it would break the stamping press”.

Tesla also shared some technical information about Ultra Hard 30x cold-rolled stainless steel

In one aspect, a steel alloy composition is described. The composition includes Fe, a hardness is at least about 400 HV, and an Epit-Eocp corrosion resistance of at least about 500 mV in a 3 wt% sodium chloride aqueous solution.

In some embodiments, the hardness is about 420 HV to about 500 HV. In some embodiments, the Epit-Eocp corrosion resistance is about 520 mV to about 800 mV. In some embodiments, the Epit-Eocp corrosion resistance is about 520 mV to about 600 mV. In some embodiments, the composition has a yield strength of at least about 1100 MPa. In some embodiments, the composition has a ductility of at least about 60° bend angle at 1.8mm thickness. In some embodiments, martensite formation begins at about 260 K to about 340 K. In some embodiments, martensite formation begins at about 260 K to about 320 K. In some embodiments, the composition has at least about 12 vol% martensite. In some embodiments, the composition has a yield strength of at least about 1100 MPa.

References:

1-https://www.sae.org/news/2020/06/tesla-cybertruck-stainless-steel

2-https://www.tesla.com/cybertruck

3-https://electrek.co/2023/10/11/tesla-cybertruck-stainless-steel-supplier-revealed/

4-https://stampingsimulation.com/forming-stainless-steel-tesla-cybertruck/