It can be difficult to keep track of the progress being made in robotics, but one useful (if informal) marker is how good machines are at assembling Ikea furniture.

Why? Because putting together your average Billy bookcase involves skills that are intuitive for humans but challenging for robots. Figuring out how a number of components fit together to make a finished product is basically one big 3D puzzle involving complex movements and the manipulation of delicate items like pins and screws. For bigger pieces of furniture, you also have to coordinate multiple actors. (Although admittedly, robots find this part easier than humans.)

With that in mind, here’s your latest Ikea Robot Assembly update: they’ve got better again.

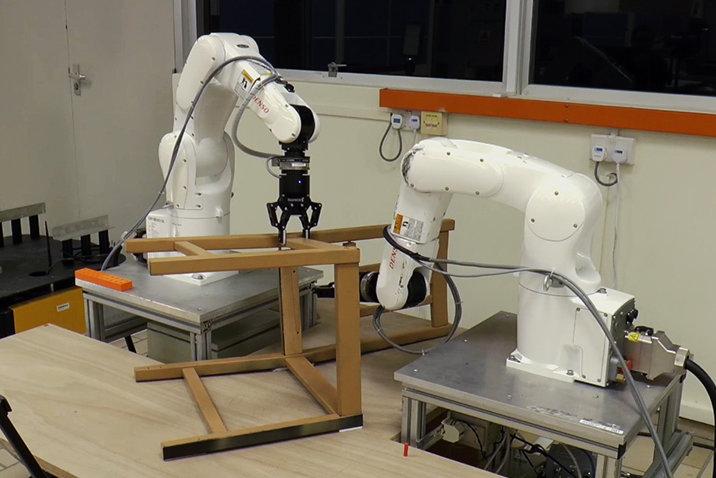

In a paper published today in Science Robotics, researchers from Nanyang Technological University in Singapore describe how they instructed a pair of industrial robot arms to put together a Stefan chair from Ikea “with no special provisions for robotic assembly.” The arms used 3D cameras to identify and track individual pieces, and force sensors to make sure they weren’t crushing anything. All in all, assembly of the chair took around 20 minutes. So, not as fast as a human, but not too shabby.

The team from Nanyang Technological University programmed a robot to create and execute a plan to piece together most of Ikea’s $25 solid-pine Stefan chair on its own, calling on a medley of human skills to do so.

The work is a step forward from previous Ikea assembly systems, says Dr. Francisco Suárez-Ruiz, one of the researchers involved. Compared to MIT’s IkeaBot system, the furniture being assembled was more complex. And compared to work done by the same Singapore team in 2015, the assembly is more autonomous.

He and his Nanyang colleagues who worked on the study, Francisco Suárez-Ruiz and Xian Zhou, aren’t alone.

In recent years, a handful of others have set out to teach robots to assemble Ikea furniture, a task that can mimic the manipulations robots can or may someday perform on factory floors and that involves a brand many know all too well.

“It’s something that almost everybody is familiar with and almost everybody hates doing,” said Ross A. Knepper, an assistant professor of computer science at Cornell University, whose research focuses on human-robot interaction.

The results of NTU’s efforts are published in Science Robotics.