Composite structures have excellent strength to weight ratios and are used in many applications, including most of the airframe in modern aircraft as shown in Figure 1 (above).

However, there are significant and obvious complicating features when trying to perform structural analysis of these structures:

1. Composite construction consists of a stack-up of thin laminae.

2. Each lamina has unidirectional fibers in a matrix; can also have woven fibers.

3. The fiber directions in each lamina can and normally do have different orientations, used to tailor the strength and stiffness of the composite to match the loading environment (Figure 2).

Figure 2: Composite Fiber Orientation Per Lamina

A micromechanical approach for modelling composites, where the mesh is fine enough to model the individual fibres, is typically not feasible and thus is usually performed in research studies. Most practical composite structural analysis is performed using a

There are several general

1. Layered shells.

2. Layered solids.

3. Solid elements (one or more element per lamina).

The use of layered shell elements is the most efficient approach to both generating composite finite element models, and solving them. Layered shells use classical lamination theory (CLT) to model the structural response of an entire laminate based on the definition of each individual lamina. The main assumptions are that the displacements are continuous across lamina boundaries (no relative slip between lamina), and the laminate is governed by shell theory. These assumptions result in a linear through-thickness variation of strain, but the stress variation can be discontinuous at lamina boundaries, as represented in Figure 3.

Figure 3: Strain and Stress Variation in CLT

Note that a

Using layered shells to model composite structures works well for thin bodies, but as the part becomes thicker, the assumptions of shell theory become a limitation. For example, thin shells have a ratio of the radius of curvature (or smaller span length for flat shells) to the thickness of 20:1 or greater, and thick shells can be valid down to a ratio of 5:1. For layered geometry with smaller ratios, the second approach of using layered solids is a more accurate strategy. Layered solids can model multiple lamina, and unlike shells, the finite element model can use multiple stacked elements to create the full composite section. The three-dimensional formulation provides prediction of the full strain and stress tensors, but this approach will likely require more work in setting up the model and in solving the analysis.

The challenges of using layered solid elements are many. The solid mesh must be created so that the direction of the stack-up within the element is specified correctly. Unlike shells, the through-thickness direction is not obvious, and the finite element code may require a particular through-thickness orientation. Since solid layered elements can be stacked, the definition of the layered sections may require significant manual labor, requiring brick meshing that can be very tedious to generate for complex geometry.

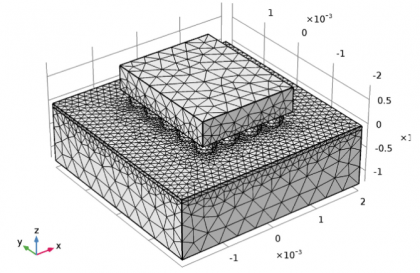

The third approach is to use one or more solid elements within each lamina. This is the more accurate approach, since each element will be contained within one lamina and thus no assumptions are required to model layered stiffness. Detailed three-dimensional stress and strain tensors can be directly calculated, including normal and shear interlaminar stresses, without the need for any special assumptions or approaches. However, the obvious drawback is that the number of elements needed to model the composite structure will most likely be extremely high. And, like any composite model, directional material properties must be defined, and local features like ply drop-offs and inserts will complicate the modeling effort. An example is shown in Figure 4.

Figure 4: Solid Elements Modeled Within Each Lamina

So, it should be clear by now that the main challenge of building composite models is the amount of detail required to define the layered geometry and orient the material properties. However, over the past few years, special purpose composite pre- and post-processors are available to assist in building and evaluating complex composite finite element models. These codes can efficiently generate all three of the composite models that were discussed, eliminating much of the user-intensive manual work.

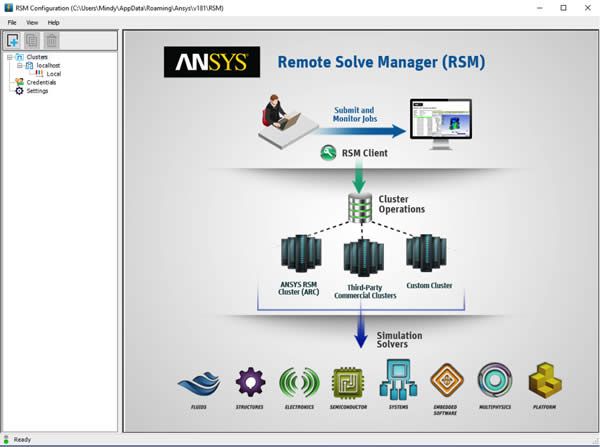

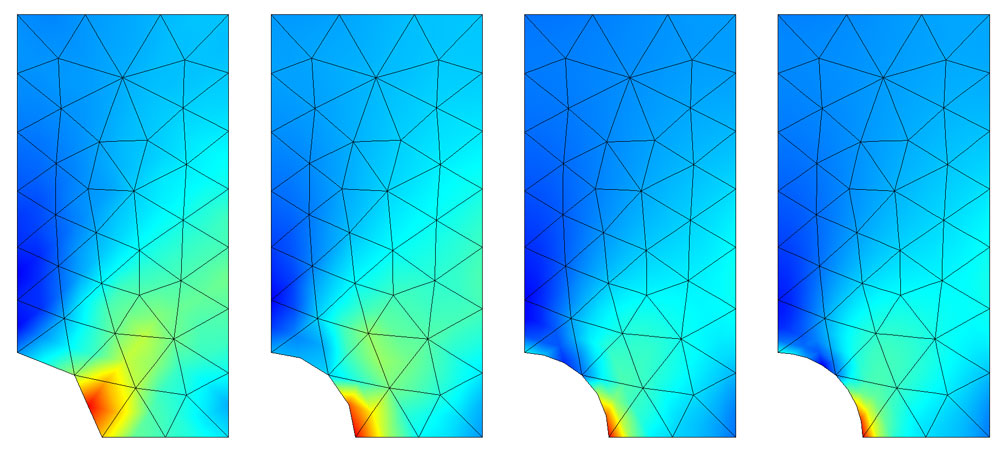

An example of a composite model generation tool is ANSYS Composite PrepPost (ACP). The approach, regardless of whether a shell or solid mesh is required, always starts with meshed surface geometry. The composite geometry and mesh is created from the surface, using defined stack-up definitions that include material, thickness, and orientation information. Ply tapering, and ply drop-offs, can readily be incorporated. An example is shown in Figure 5.

Figure 5: Starting Surface Geometry and Final Solid Composite Model

ACP can output layered shell, layered solids or a specified number of solid elements per lamina. The composite model can readily be combined with non-composite geometry, such as adjacent structures or even inserts, by dragging and dropping the component models into one analysis model. And the post-processing features are tailored for composite structures, including accurate normal and shear interlaminar stress prediction.

So, although

Source ; Caeai.com

özgün

Thank you for your comment.

We will shorty sort this out.