Figure 1: Link Thermal to Independent Structural keeping pre-Environment Branches—Alternative Ways

Introduction

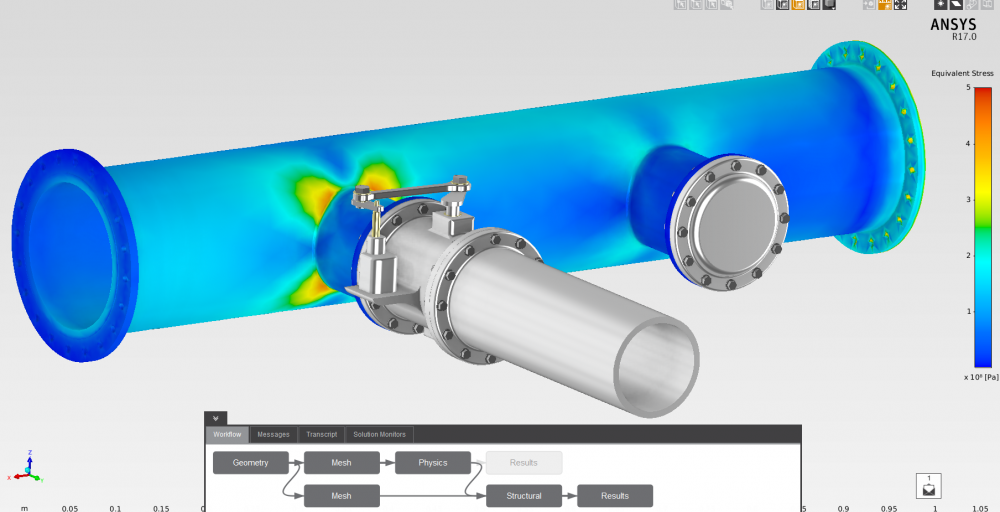

ANSYS Workbench Mechanical can link a thermal analysis to a structural analysis, sharing Engineering Data, Geometry and Model directly. When directly linked, bodies in the structural model cannot be suppressed independently of the thermal analysis, and meshing and contacts cannot be set differently.

A structural analysis can be linked at the Geometry level, but the user will have to re-do all of the Model details, including desired Coordinate Systems, Connections (including Contacts), and meshing controls. This keeps the structural analysis independent of the thermal analysis. Temperatures can be mapped.

This article explores methods that let the user keep the Model controls while maintaining an independent structural analysis, so that bodies can be suppressed, contacts and meshing can be tweaked only if desired, and temperatures are still mapped from the thermal analysis.

Details of Creating an Independent Structural System

In the Workbench project page, the usual approach to linking a thermal analysis to a downstream structural analysis is to drag-and-drop the structural analysis onto the Solution cell of the thermal analysis:

Figure 2: Drag-and-Drop a Structural System onto Solution of a Thermal System

The following familiar result has the two models directly linked. The mesh is shared. Temperatures are copied directly from the thermal analysis nodes to the structural analysis nodes. This is the result:

Figure 3: Directly Linked Thermal and Structural Systems

With the systems linked as shown above, the two models appear in a common Outline in Workbench Mechanical. Suppressing a body removes it from both the thermal and structural analysis. Changes to meshing or to contacts will affect both the thermal and structural systems.

The Outline in Workbench Mechanical shows both environments when the above direct link is employed:

Figure 4: Outline with Two Linked Environments

An alternative approach starts by linking at the Model level after detailing the thermal analysis. Branches prior to the Structural environment are inherited:

Figure 5: Thermal Linked to Structural at the Model Cell

The next step is to use Duplicate on the Structural system:

Figure 6: Duplicate the Structural System

This results in an independent Structural system:

Figure 7: Independent Structural System on the Right

The structural system on the right will inherit the Engineering Data, Geometry, and Model branches of the Thermal and middle structural models. Because the structural system on the right is now independent of the other systems, the Workbench Mechanical model can make any changes desired to Engineering Data, details of Geometry, or branches at the Model level. This avoids re-doing the meshing and other work done by the user in the Thermal analysis, potentially saving considerable time with complex models. The linked and duplicate systems should be created after the thermal analysis is meshed, and contact settings have been set as desired.

Once the Duplicate system is created, the middle structural system can optionally be removed:

Figure 8: Removing the Unnecssary Linked Structural System

In the resulting schematic, Engineering Data and Geometry cells can be optionally linked so changes propagate:

Figure 9: Independent Structural System Has the Same Model Settings

Drag-and-Drop the Engineering Data and Geometry cells from the thermal system to the structural system:

Figure 10: Optionally Linked Engineering Data and Geometry

The thermal Solution cell must be manually linked to the Setup cell of the structural analysis (drag-and-drop):

Figure 11: Linking the Thermal Solution Cell to the Structural Setup Cell

The resulting structural system may need refreshing and updating with links at Engineering Data and Geometry:

Figure 12: Thermal Results Will Be Mapped to the Structural Analysis

Once the links are established, a refresh will bring the structural system up to date.

Refresh and Update as required—Model Cell:

Figure 13: Right-Click and Refresh the Model after Linking

As needed, refresh the Setup Cell:

Figure 14: Refresh the Setup

Inside Workbench Mechanical with the structural model, the Imported Body Temperature can be observed:

Figure 15: Mapped Temperatures

When the same mesh is used, temperature mapping is usually simple. If the thermal model has finite contact conductance for a contact pair, a temperature drop can occur across the pair, and users should ensure that temperatures from one side of a contact pair do not end up on the other side. An identical mesh may help.

Because the Model cell for the structural system is not linked to the Model cell of the thermal system, bodies in the structural system can be suppressed as desired:

Figure 16: Suppressing a Chosen Body in the Structural System

After suppressing one or more bodies, temperatures can be re-imported (right-click and request Import Load):

Figure 17: Temperatures in Non-Suppressed Bodies

If desired, alternative meshing can be applied to the structural analysis, and contact pairs can be reset to other behaviors.

Inside the structural analysis, users sometimes want to suppress bodies from the thermal analysis that represent insulation or pockets of air, and are not wanted in the structural analysis.

Conclusions

Workbench can link various systems in the Project Schematic. The usual means of linking means that the Model cells are linked, and the various analysis systems must use the same bodies, mesh, contacts and other Model level settings.

Workbench Mechanical can work with an independent Model branch if a certain series of steps are employed to create a duplicate of a downstream linked system in the Project Schematic. The duplicate system inherits the Model settings, but can then be modified independently. Solution results from an upstream system can be manually linked to the Setup cell of the duplicate system. The duplicate system Model branch can be modified as desired, including changes to suppressed bodies, meshing controls, and contact or connection objects.

This procedure would only be used when a user wants to have independent control of the Model branches in the downstream structural system. Ordinarily, the structural system would be directly linked to the thermal system.

Source: simutechgroup

Chandra Firmansyah

Hey, can i ask some question. I have some conditions, if I want to make a welding simulation, so I can use transient thermal analysis right? and after that i want to see the distorsion effect of it, can I just linked it to transient structural?

Cansu

Tam tersini yapmak mümkünmü? Yani statik analiz sonuçlarını termal analiz sonuçlarına bağlayabilirmiyiz?

özgün

Merhabalar,

Elbette static structural sonuclarini da thermal analize baglayabilirsiniz.