A new 3D-printing technique can make metals stronger, without reducing ductility, according to researchers.

An international team of scientists, including researchers from the University of Birmingham, Stockholm University and Zhejiang University in China, took advantage of the ultra-fast cooling rate of 3D-printed metals to create the improved mechanical properties.

“Strength and ductility are natural enemies of one another; most methods developed to strengthen metals consequently reduce ductility,” said Leifeng Liu from the University of Birmingham, a lead author on the research, which was published in the journal Materials Today.

“The 3D-printing technique is known to produce objects with previously inaccessible shapes, and our work shows that it also provides the possibility to produce the next generation of structural alloys with significant improvements in both strength and ductility.”

The research demonstrated that cooling metals incredibly quickly resulted in a ‘non-equilibrium state,’ which created microstructures within the metal that made it stronger. This included a dislocation network – tiny twists and tangles that changed the way the metals behaved under stress.

Metals that are cooled down so quickly result in a so-called non-equilibrium state, allowing for some amazing microstructures like the sub-micro-sized dislocation network – which was revealed in this paper to be the main reason of the improved mechanical properties.

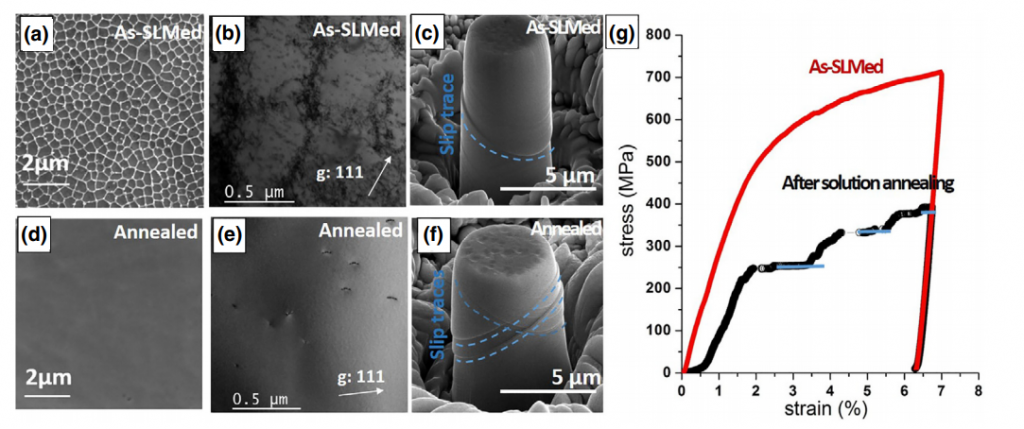

Figure: Micropillar compression test result. (a and b) SEM and TEM images of the microstructure of the as-SLMed 316LSS. (c) Compression tested micropillar of the asSLMed

316LSS. (d and e) SEM and TEM images of the microstructure of the annealed 316LSS. (f) Compression tested micropillar of the annealed 316LSS. (g)

The engineering stress–strain curves obtained from two micropillars. The as-SLMed sample shows almost doubled yield strength and much smoother plastic

flow behavior than the annealed sample.

By using this technique to create steel beams, with an additive manufacturing technique called selective laser melting, the researchers were able to break the trade-off between strength and ductility.

“This work gives researchers a brand-new tool to design new alloy systems with ultra-mechanical properties,” continued Liu. “It also helps metal 3D printing to gain access into fields where high mechanical properties are required, like structural parts in aerospace and the automotive industry.”

Here is the academic paper:

http://www.sciencedirect.com/science/article/pii/S1369702117304625