Mechanical engineers put an Oreo’s cream filling through a battery of tests to understand what happens when two wafers are twisted apart. When you twist open an Oreo cookie to get to the creamy centre, you’re mimicking a standard test in rheology — the study of how a non-Newtonian material flows when twisted, pressed, or otherwise stressed. MIT engineers have now subjected the sandwich cookie to rigorous materials tests to get to the centre of a tantalizing question: Why does the cookie’s cream stick to just one wafer when twisted apart?

“There’s the fascinating problem of trying to get the cream to distribute evenly between the two wafers, which turns out to be really hard,” says Max Fan, an undergraduate in MIT’s Department of Mechanical Engineering.

The researchers also measured the torque required to twist open an Oreo, and found it to be similar to the torque required to turn a doorknob and about 1/10th what’s needed to twist open a bottlecap. The cream’s failure stress — i.e. the force per area required to get the cream to flow, or deform — is twice that of cream cheese and peanut butter, and about the same magnitude as mozzarella cheese. Judging from the cream’s response to stress, the team classifies its texture as “mushy,” rather than brittle, tough, or rubbery.

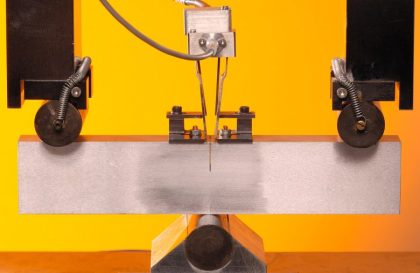

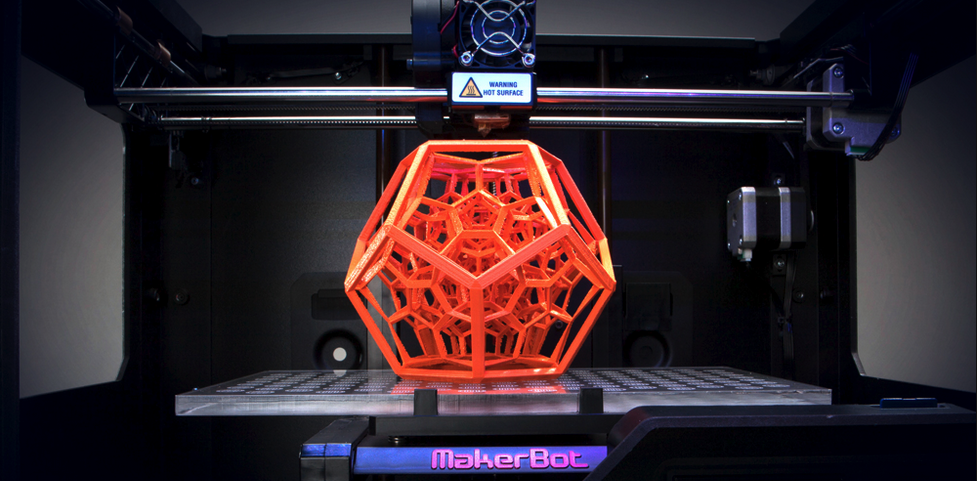

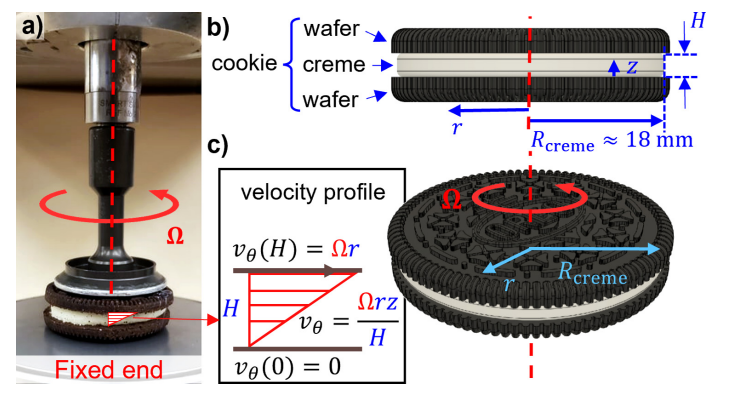

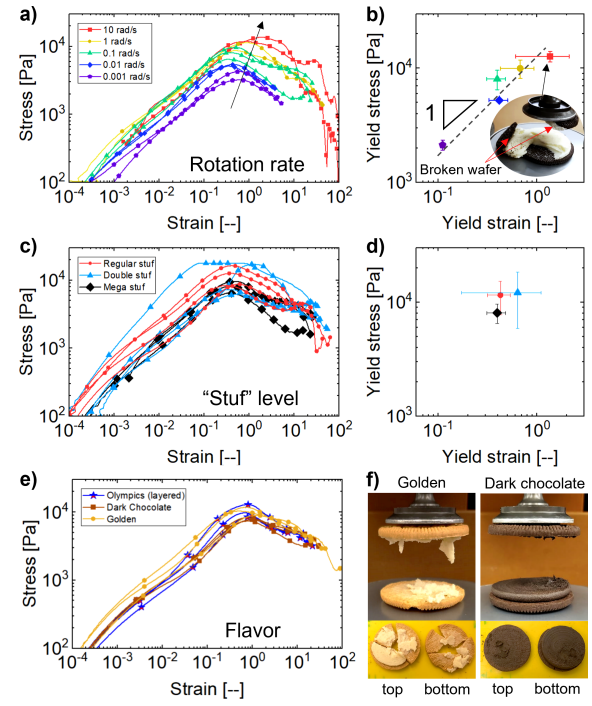

In an experiment that they would repeat for multiple cookies of various fillings and flavors, the researchers glued an Oreo to both the top and bottom plates of a rheometer and applied varying degrees of torque and angular rotation, noting the values that successfully twisted each cookie apart. They plugged the measurements into equations to calculate the cream’s viscoelasticity, or flowability. For each experiment, they also noted the cream’s “post-mortem distribution,” or where the cream ended up after twisting open.

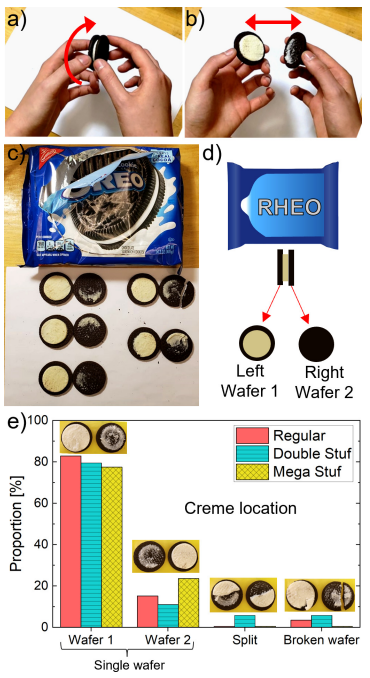

facing left for regular, right for double, and up for mega (where rows are oriented vertically rather than horizontally) in standard size packages.

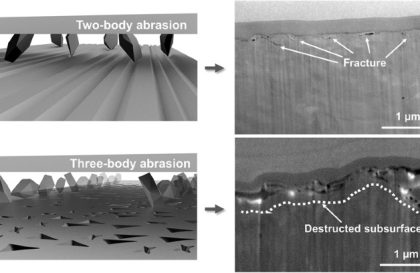

layered composite with two solid wafers enclosing a central cream layer. When one wafer is rotated relative to the other, the creme deforms in torsion. (c) The resulting velocity field within the creme is a function of applied rotation rate, material height, and radius from the center. In this figure, red colors indicate kinematic properties, and blue colors indicate geometric properties in the colored web version of this article

Conclusion

Through a series of experiments with a laboratory rheometer used to hold whole Oreo cookies, they determined that creme distribution upon cookie separation by torsional rotation is not a function of rate of rotation, creme “stuf” (i.e., filling height H) level, or flavor, but was mostly determined by the preexisting level of adhesion between the cookie creme and each wafer. In most cases, creme delaminated from the wafer with a preferential orientation with respect to the package within any one box, allowing prediction of failure direction with 80% accuracy. Despite the consistent failure mode, there was some amount of cookie-to-cookie and box-to-box variation in failure stress and strain. Apparent reflow of creme due to unknown causes had the most significant effect in altering failure type, allowing for improved creme–wafer bonds and subsequent cohesive failure of the creme.

As for the cookie itself, she suggests that if the inside of Oreo wafers were more textured, the cream might grip better onto both sides and split more evenly when twisted.

“As they are now, we found there’s no trick to twisting that would split the cream evenly,” Owens concludes.

This research was supported, in part, by the MIT UROP program and by the National Defense Science and Engineering Graduate Fellowship Program.

Original article

https://aip.scitation.org/doi/10.1063/5.0085362