The practice is considered one of the key instruments of learning. Most commonly it is believed that theoretical education itself is not enough to prepare students to real engineering life where they struggle to overcome difficulties. Having a workshop experience is also important because it leads students to get a better understanding of the modules of undergrad education.

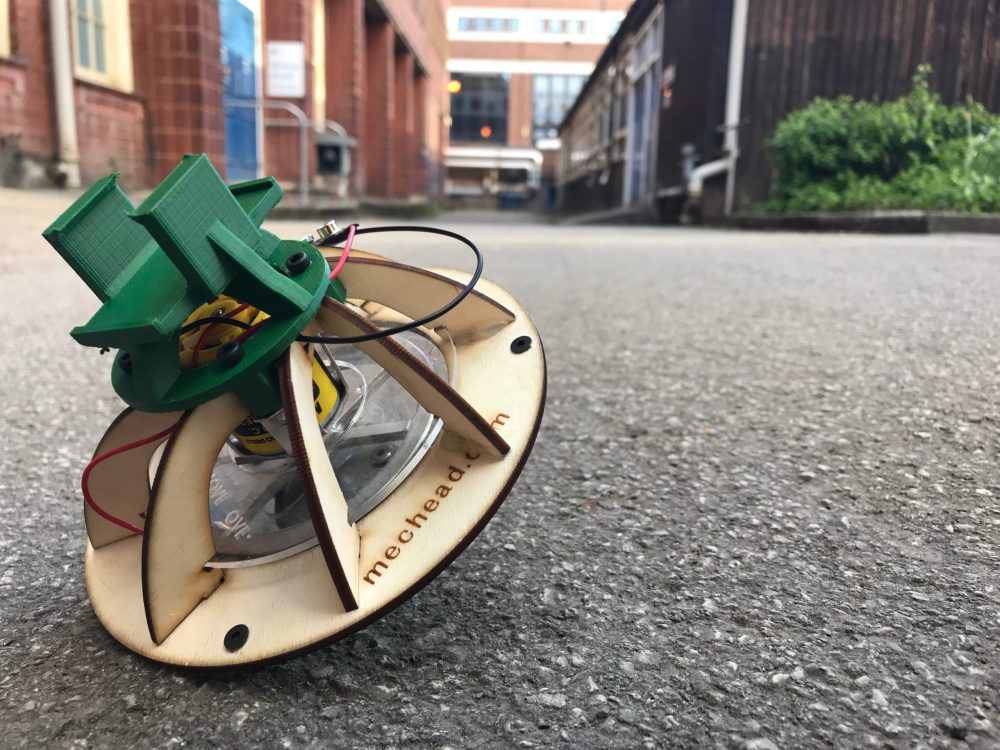

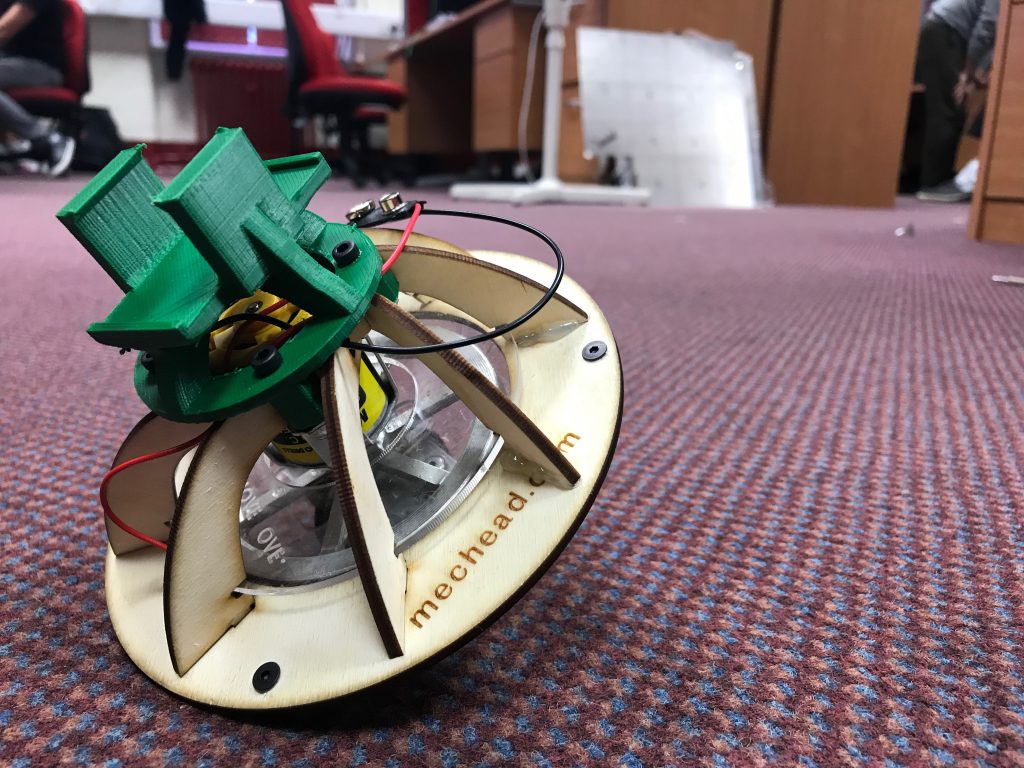

Therefore, The Department of MEE in the University of Sheffield has been teaching Engineering Application module inside Project Space where students at the University of Sheffield are manufacturing and testing a Gyrocar using a range of manufacturing techniques.

Engineering application

During the project, students learn and practice the processes of;

- Milling

- Drilling

- 3D printing

- Laser Cutting

- Turning

- Vacuum forming

- Casting

- Routing

- Blanking

- Marking out

- Sheet metal work

- Fastening

- Tapping

- Soldering

- Assemble

How the Gyrocar Works?

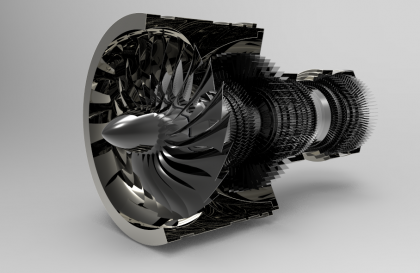

The gyroscope effect is an application of angular momentum. There are many common instances of the gyroscope effect, whether you were aware of it or not, spinning tops, bicycle, compasses. The essence of gyroscope effect is that if an object is spinning around one axis, and a torque is applied about a second axis, the object will rotate about the third axis. The gyrocar works in the same way- it has a high inertia flywheel inside it, driven by a motor, that rotates about the vertical axis and giving it angular momentum. The faster the rotation, the more angular momentum, and more resistant to changes in orientation, and the more stable the Gyrocar.

This year, we (mechead.com) had a chance to make our own Gyrocar and test it in the track designed for this module. Building our own car took approximately 4-5 hours, however, it has to be kept in mind that I have been working in this module as a teaching assistant for 2 years and we have so much experience about the problems and difficulties which might occur. Normally, It is a 4-session-module (14 hours) for first-year engineering students. Therefore, they have plenty of time to finish their tasks and test the gyrocar

The final step of the gyrocar experience is obviously testing. By the end of the module, your car should finish two laps without getting off the track. Two lap time of students’ gyrocars varies between 7 and 20 seconds depending on how accurately cars are manufactured. There are a couple of problems that students are facing, such as; misaligning the components, assembling faults, balancing the flywheel. However, we managed to finish 2 laps in 9:64 seconds.