The manufacturing equipment and materials have been developing since human beings existed. A number of conventional methods are being used in manufacturing. However, most of them have a large number of drawbacks in terms of their workability capabilities. Therefore, sometimes the workflow of the material manufacturing consists several processes which increase the labour and fabricate costs. Recently, a new method 3D printing has been highlighted with the developments of material science and artificial intelligence.

History

Despite the fact that 3D printing is considered relatively new technology, it has been used for 30 years. Chuck Hull invented the first 3D printing process called ‘stereolithography’ in 1983. In a patent, he defined stereolithography as ‘a method and apparatus for making solid objects by successively “printing” thin layers of the ultraviolet curable material one on top of the other’. This patent only focuses on ‘printing’ with a light curable liquid, but after Hull founded the company ‘3D Systems’, he soon realized his technique was not limited to only liquids, expanding the definition to ‘any material capable of solidification or capable of altering its physical state’. With this, he built the foundation of what we now know today as additive manufacturing (AM) – or 3D printing.

How does the process work?

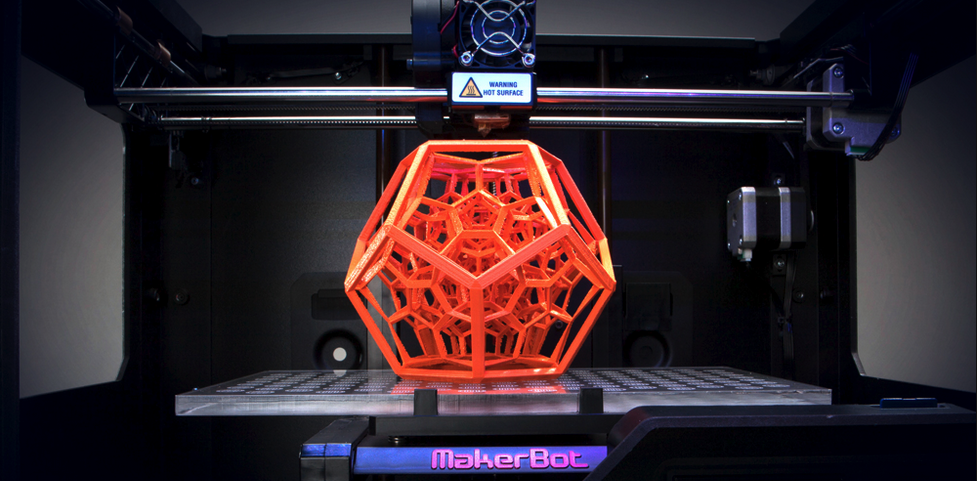

Every 3D print starts as a digital 3D design file – like a blueprint – for a physical object. Trying to print without a design file is like trying to print a document on a sheet of paper without a text file. This design file is sliced into thin layers which is then sent to the 3D printer.

From here on the printing process varies by technology, starting from desktop printers that melt a plastic material and lay it down onto a print platform to large industrial machines that use a laser to selectively melt metal powder at high temperatures. The printing can take hours to complete depending on the size, and the printed objects are often post-processed to reach the desired finish.

Available materials also vary by printer type, ranging from plastics to rubber, sandstone, metals and alloys – with more and more materials appearing on the market every year.

Sales

Estimated 3D printer sales per year from 2007 to 2015. Source: Wohler’s Report 2015; Gartner

Until 2009 3D printing was mostly limited to industrial uses, but then the patent for fused deposition modeling (FDM) – one of the most common 3D printing technologies – expired.

Through the RepRap project’s mission to build a self-replicating machine, the first desktop 3D printer was born. As more and more manufacturers followed, what once cost $200,000 suddenly became available for below $2000, and the consumer 3D printing market took off in 2009.

3D printer sales have been growing ever since, and as additive manufacturing patents continue to expire, more innovations can be expected in the years to come. There are now roughly 300,000 consumer 3D printers in the world – and this figure is doubling every year.

Pros and Cons

It’s crucial to understand that 3D printing is a rapidly developing technology, which comes with its set of inherent benefits, but also lags behind traditional manufacturing processes in some aspects. We collected examples from both sides to help you get a grasp of these factors and to see where the technology is headed in the near future.

Pros

- Allow complex designs

- No tools, moulds lower fixed costs

- Easy to customise each item and product

- Less waste

- Speed and ease of prototyping

Cons

- Higher cost for large product runs

- Limited material availability

- Less strength and endurance

- Lower precision