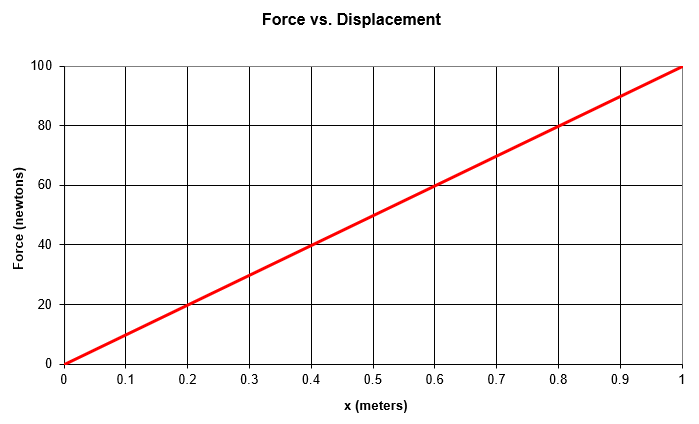

We often see linear and nonlinear analysis in academic studies, however, how well do you know about it?

1. Linear static analysis

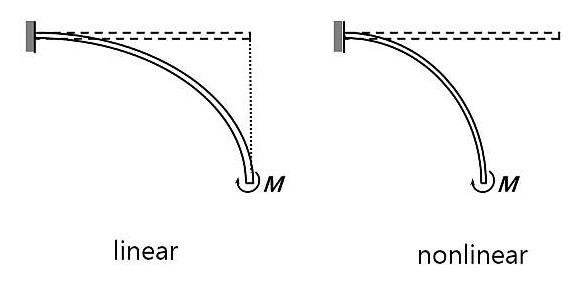

A linear static analysis is an analysis where a linear relation holds between applied forces and displacements. In practice, this is applicable to structural problems where stresses remain in the linear elastic range of the used material. In a linear static analysis the model’s stiffness matrix is constant, and the solving process is relatively short compared to a nonlinear analysis on the same model. Therefore, for a first estimate, the linear static analysis is often used prior to performing a full nonlinear analysis.

2. Nonlinear analysis

A nonlinear analysis is an analysis where a nonlinear relation holds between applied forces and displacements. Nonlinear effects can originate from geometrical nonlinearity’s (i.e. large deformations), material nonlinearity’s (i.e. elasto-plastic material), and contact. These effects result in a stiffness matrix which is not constant during the load application. This is opposed to the linear static analysis, where the stiffness matrix remained constant. As a result, a different solving strategy is required for the nonlinear analysis and therefore a different solver.

Modern analysis software makes it possible to obtain solutions to nonlinear problems. However, experienced skill is required to determine their validity and these analyses can easily be inappropriate. Care should be taken to specify appropriate model and solution parameters. Understanding the problem, the role played by these parameters and a planned and logical approach will do much to ensure a successful solution.

The source of this nonlinearity can be attributed to multiple system properties, for example, materials, geometry, nonlinear loading and constraints. Here are some examples…

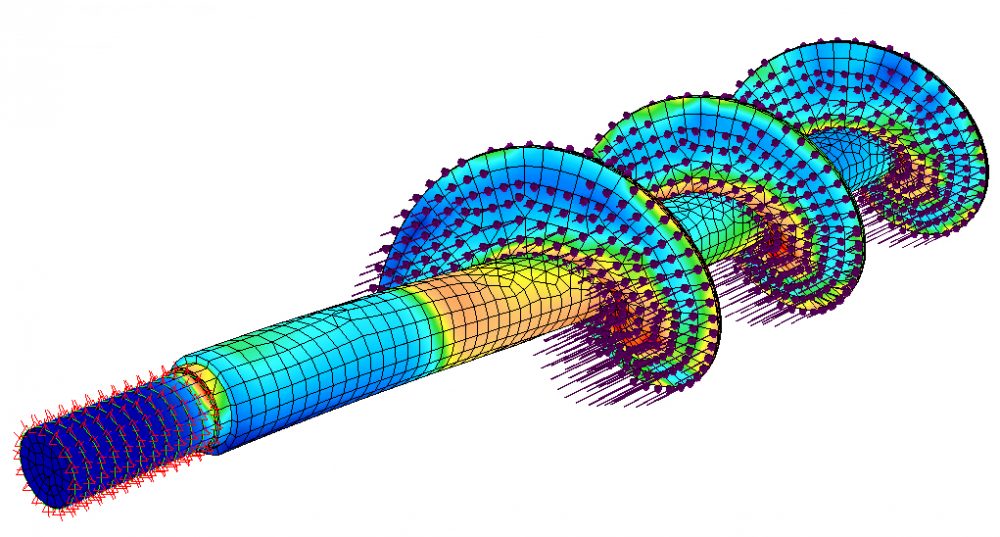

2.1 Geometric Nonlinearity

In analyses involving geometric nonlinearity, changes in geometry as the structure deforms are considered in formulating the constitutive and equilibrium equations. Many engineering applications such as metal forming, tire analysis, and medical device analysis require the use of large deformation analysis based on geometric nonlinearity. Small deformation analysis based on geometric nonlinearity is required for some applications, like analysis involving cables, arches and shells. This is often controlled by Large Deflection in Ansys

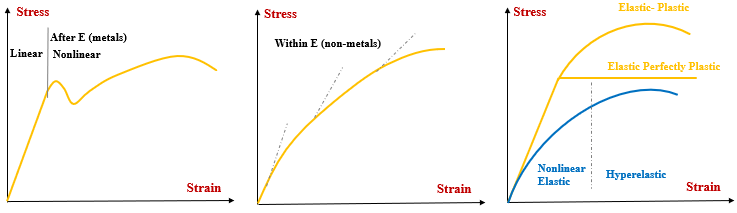

Material Nonlinearity

Material nonlinearity involves the nonlinear behaviour of a material based on a current deformation, deformation history, rate of deformation, temperature, pressure, and so on. Examples of nonlinear material models are large strain (visco) elasto-plasticity and hyperelasticity (rubber and plastic materials).

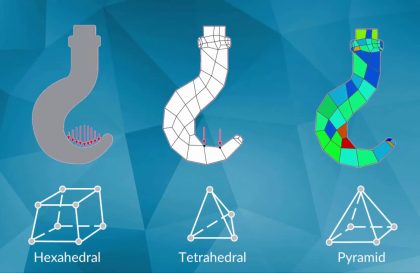

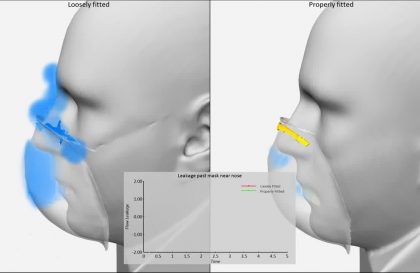

Constraint and Contact Nonlinearity

Constraint nonlinearity in a system can occur if kinematic constraints are present in the model. The kinematic degrees-of-freedom of a model can be constrained by imposing restrictions on its movement.